Hello,

Sign In

Almost all lithium-ion batteries are rechargeable because they are shaped like a memory effect and have the ability to store a charge. Portable electricity is provided by lithium and lithium-ion batteries or cells. Both work by chemically storing electrical charges; charges flow from the cathode of a battery to its anode when you connect their electrodes to a wire, creating an electric current. Each type of lithium-ion battery has advantages and disadvantages depending on the configuration.

Charging lithium batteries is not easy and safe; this problem led to the invention of lithium-ion batteries. Before they fail, they can be charged several times. However, lithium batteries cannot be recharged, but their capacity is greater than that of lithium-ion batteries. They have a higher power density than lithium-ion batteries. Compared with lithium-ion batteries, lithium batteries use lithium metal as the anode, and various other materials are used to form the anode. Lithium-ion batteries are weakened because they have a shelf life of approximately three years, after which they are useless, but around these years they can be easily recharged.

There is a difference between a lithium battery and a lithium-ion battery because a lithium battery contains lithium metal as an anode so they are not rechargeable whereas lithium-ion batteries do not contain such metal but instead contain ions that are ionized at their respective electrode which is why they are rechargeable.

After a number of experiments and user feedback, it has been observed that a lithium-ion battery can hold a charge for many months and will keep a charge. However, it is safer to store a partially or fully charged lithium-ion battery. Sometimes a lithium-ion battery with a very low charge is stored for a long time (many months) and its voltage slowly drops below a level at which it can be recharged due to a built-in safety mechanism. If you plan to store the battery for several months, it is recommended that you remove it and charge it with compatible charger after a few months. It would be better to use the battery every few months and then leave it partially or fully charged so that you can use it easily and not create any problems for you.

The first commercial lithium-ion batteries entered the market in 1991, and in the nearly 30 years since then, we have seen rapid progress. As a result, we have many different technologies and types of batteries, divided by the type of construction and materials used. To properly handle batteries, it is important to know what type you have in your hands, and it is very important to pay attention to this.

18650 form factor lithium-ion cells from a laptop. Such sets are usually joined by spot welding of nickel strips.

Lithium-ion or Li-ion batteries are commonly referred to as the entire rechargeable lithium battery technology, but traditional cells with a cylindrical metal case are often referred to as such. One option is the venerable 18650, but in general, there are many options and sizes. Their strong hulls have made them popular for use in vehicles, as the latter experience significant physical stress.

Lithium polymer, or Li-Po, is a lithium-ion battery that uses a polymer electrolyte instead of a liquid one. Thanks to this, they can be made in the form of containers of various shapes. This flexibility makes them useful for applications such as smartphones and tablets that require a high-capacity, flat-shaped battery. They are also often used in radio-controlled models since their light weight gives a significant advantage to aircraft.

Lithium polymer pack batteries for use in radio-controlled models.

Lithium-HV, or high voltage lithium batteries, are lithium polymer batteries that use a special silicon-graphene additive on the positive terminal, thanks to which it is not damaged by high voltage. If you charge most lithium batteries to voltages above 4.2 V, they will lose a lot of capacity and their life will be noticeably reduced. Using this additive, you can charge cells up to 4.32 V without such negative consequences. Increasing the voltage gives about a 10% increase in energy density compared to conventional lithium polymer batteries.

Lithium iron phosphate batteries, or LiFePO 4, use slightly modified chemistry so they can handle more charge/discharge cycles at the expense of a slightly lower energy capacity. They work best in the 3.0V to 3.65V range rather than the typical 3.0-4.2 range found in standard lithium-ion chemistry. This and the very flat discharge curve make them ideal for replacing 12V lead batteries in many applications, and four are used instead of the original six. They are usually more stable, and less prone to self-discharge and loss of capacity over time.

You can check in the following link the multiple advantages of using lithium batteries in the forklifts of your operation, these are the most relevant:

Lithium-ion battery cells can be of different chemical compositions. The most common compositions in the forklift industry and the automotive sector are:

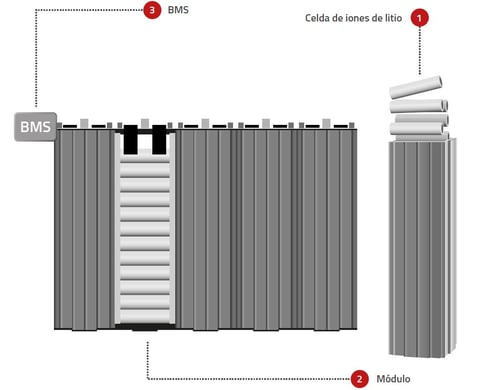

A lithium-ion battery consists of multiple cells that are assembled together in a module. Depending on the size of the battery, the modules are connected in series and form a battery system. Each module is equipped with mechanical and electronic security systems. In addition, the complete battery system has a superior BMS (BMS – Battery Management System) that controls the total activity of the battery.

The BMS system cooperates and communicates with the equipment. If any cell in a battery module were to fail or be at risk such as overheating, the power supply would shut down and the truck would display an error code.

The lithium-ion battery works like a traditional battery. However, the advantage is that the energy delivery is maximum all the time, no matter how little charge the battery has left. With a traditional lead acid battery, the rig’s ability to drive decreases the more the battery is discharged, affecting both speed and lifting capacity.

Copyright © 2023 Muller Energy. All rights reserved.

Lorem ipsum dolor sit amet, consectetur adipisi cing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.